What is staining as it relates to aqueous parts cleaning you might ask? It is an industry term companies use when an aqueous bath leaves soils, or oily residues, on a part after the parts have been through a complete cleaning cycle. For all the innovations that have made the cleaning industry what it is today, aqueous parts cleaning is relatively straightforward. Soiled parts go into the parts washer, a process such as high-pressure spray or immersion agitation is performed by the machine and, ultimately, the parts come out clean at the end of the process.

As we have all learned by now an aqueous bath will get dirty over time and will not remain effective without periodic maintenance. Soils will continue to build up with each subsequent cleaning, and if the bath goes too long without being emptied and recharged, parts may come out stained. Depending on soil load and the level of cleanliness desired, the frequency that the bath needs to be changed may increase, while cost-effectiveness decreases. This is when techniques to extend bath life, such as oil skimming and water filtration, come into play.

Oil skimming

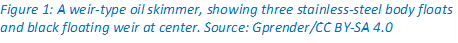

Oil skimming is a simple and relatively inexpensive method to extend bath life. It is effective for soil or chemistry combinations that cause oil splitting — oils separating out of the solution and floating upon the surface. Those oils can be pulled out of the bath by a skimming object, or floated over a weir and deposited into a chamber.

The skimming technique involves plunging a belt or disc through the surface of the bath, causing floating soils to stick to it. Soils are then removed from the skimming object by a thin blade that works like a spatula, and pushed into a receptacle to avoid recirculation in the bath.

The weir technique catches overflow and provides a separate chamber for oil separation to occur. However, for machines that use high temperatures with high pressure spray or rely upon turbulence within the bath to clean, an overflow weir is only effective when the bath is not in use. Ultrasonic washers, by contrast, can use an overflow weir during bath operation. The weir can also be used in combination with an oil skimmer for even more added effectiveness.

Water filtration

Water filtration, which removes soils with a filter, is a more robust approach to the staining problem. It can also be costlier and requires a bit of caution depending on the technique employed.

Different types of filtration target different levels of soil separation. Size-exclusion filters use small pores, measured in microns, to address suspended solid particulates. While they do not filter out dissolved materials, this type of filtration is the most common approach and the most effective. There are also more technically exacting filters that work at the molecular level, separating molecules of water from molecules of soil. An example of this type of filtration is a kidney dialysis machine, which excludes proteins and blood cells but allows waste in the blood and extra fluid to pass through.

Additional considerations

Choosing the most cost-effective approach to minimize staining and maximize bath life requires consideration of many variables. Primarily, if it costs more to skim or to filter than it does to periodically recharge the bath, it is more prudent to do the latter.

Incorporation of an oil skimmer is a sensible approach if, for example, the parts to be cleaned are torn from an engine or pulled from greasy process equipment. Yet, one should consider just how clean the parts need to be. The answer for a conveyer belt gear that needs to be maintenance cleaned will likely be different than for a part that is an essential component of a rocket-launching system.

In the end, a solid understanding of the needs and economics of the overall process is the best way to determine which approach is most effective.

For more information on finding solutions to parts staining and other aqueous cleaning issues, contact ArmaKleen at armakleen.com/ask-andy.